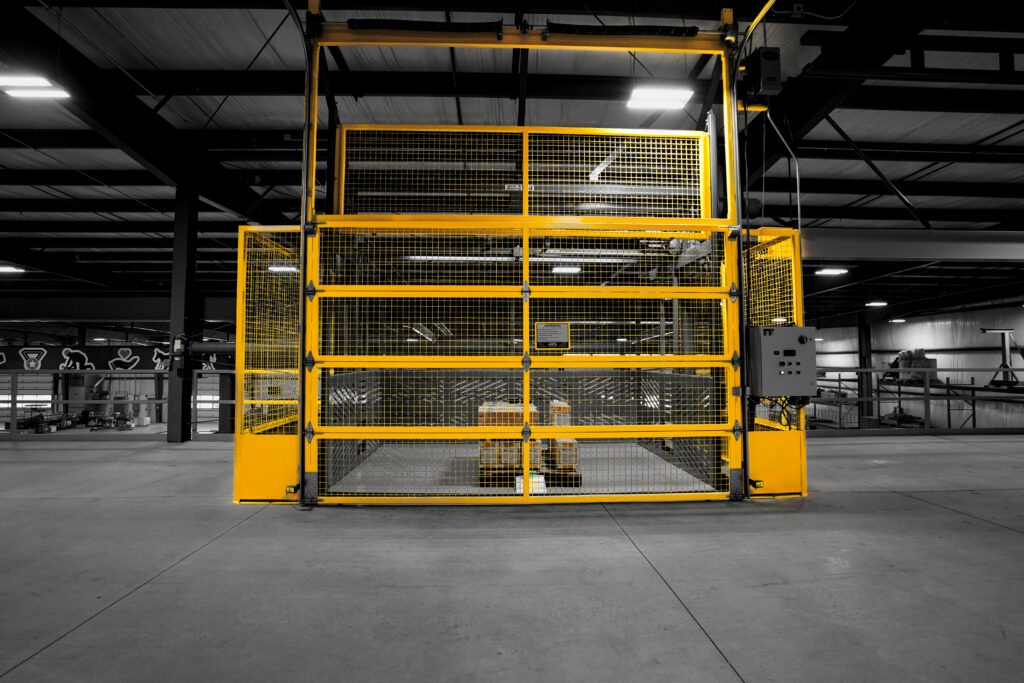

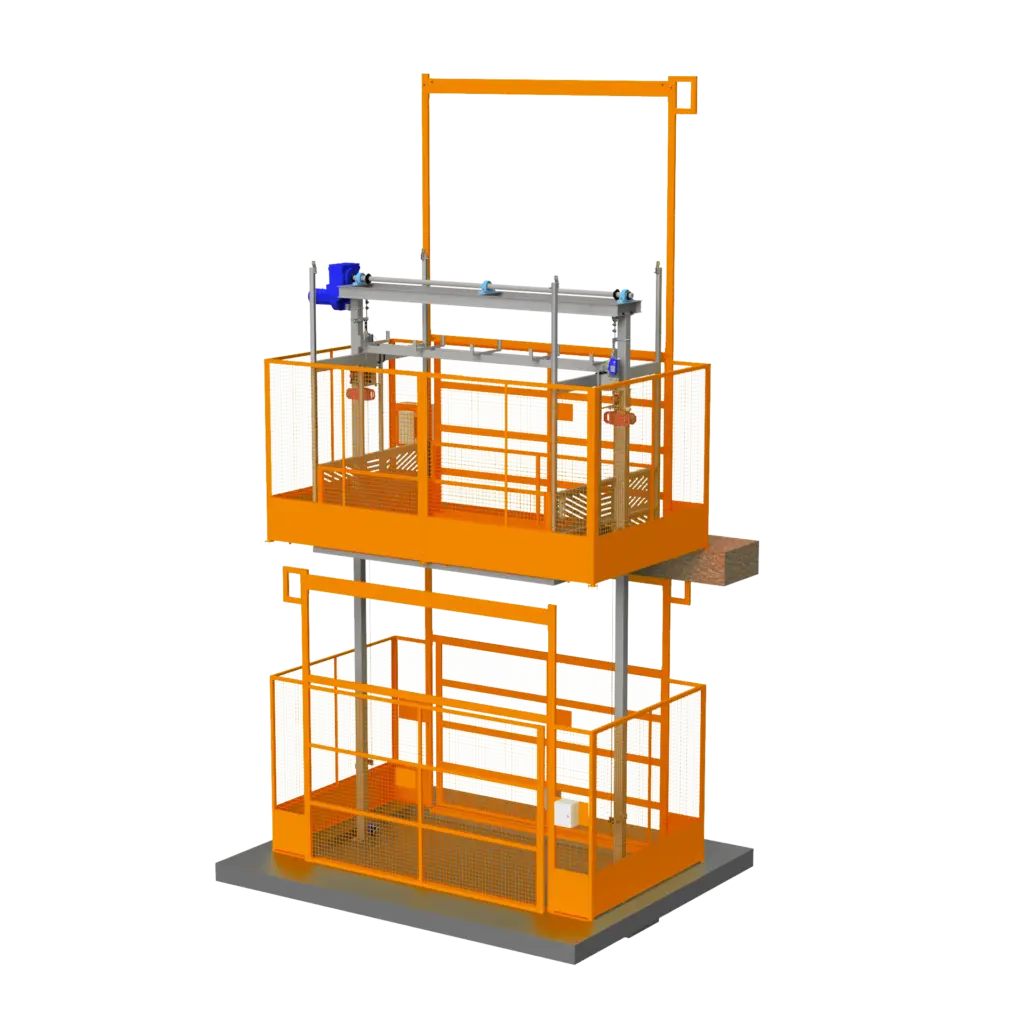

Apex Vertical Reciprocating Conveyors

Effortlessly transfer materials

Whether you're moving heavy pallets or odd sized materials, Apex VRC's enhance your productivity while prioritizing safety.

Specs

Capacity

Up to 5,000 Lbs

Lift Speed

Up to 26 FPM

Drive System

Hoist or Geared

Control Type

Push Button

Power Supply

460V

Options

Multiple Frame Sizes

Find a frame size for your application.

Carriage Safety Gates

Ensure loads are secure through transport.

Exterior Safety Gates

Protect production employees from moving parts.

Innovative product features

Precise VFD Control

Our control panel, equipped with a Variable Frequency Drive (VFD), enhances the operation of your Vertical Reciprocating Conveyor (VRC) by allowing for soft start and stop functionality. This feature minimizes the risk of sudden jolts during load transfers, ensuring smooth and safe operation. The VFD enables precise control over speed and acceleration, which significantly reduces wear and tear on the system and enhances the safety of load handling.

Advanced Load Monitoring

Our load cell technology is designed to monitor the weight of materials being transferred, providing real-time data to prevent overloading of the Vertical Reciprocating Conveyor (VRC). This essential feature enhances safety by automatically limiting the VRC’s operation when the weight exceeds the specified capacity, reducing the risk of accidents and equipment damage.

Built-In Brake Device

Our innovative brake device is seamlessly integrated into the VRC frame, providing a crucial safety mechanism that prevents the carriage from crashing in the event of a drive system failure. This built-in feature engages automatically, ensuring that loads are securely halted and minimizing the risk of accidents or damage. By offering reliable protection against unexpected failures, our brake device enhances operational safety and instills confidence in your material handling processes.

Perimeter Safety Gates

Our perimeter safety gates are designed to provide maximum security for loads as they transfer between levels, ensuring safe and efficient material handling. These gates automatically enclose the carriage perimeter during operation, preventing accidental spills or falls and protecting both personnel and materials.

Gallery

Real customers. Real results.

We purchased a freight elevator from PWI for the store I manage. We have had very little service issues and they are always available to answer questions. PWI will always be a five-star in my book.

FAQs

What are the different names for a VRC Material Lift?

They are often called freight elevators although this term is discouraged because they are not intended for human passengers. Others might call it a “mezzanine lift”.

What safety features are included with VRCs?

PWI Material Lift VRCs are designed to meet OSHA standards. All VRCs come with the Starke Secondary Brake Device, which is a load arrestor. This device will act as a secondary stopping device in the event of a fall.

How expensive is a VRC?

A PWI Material Lift (VRC) will allow your production team to move materials without the added cost of a forklift or forklift operator. VRCs are extremely reliable and typical wear is not an issue. With a little maintenance, a VRC will serve your company without added expense.

Will a VRC put strain on my building?

VertiFlow VRCs are built in a self-containing structure. This means there won’t be any strain put on your building or mezzanine.