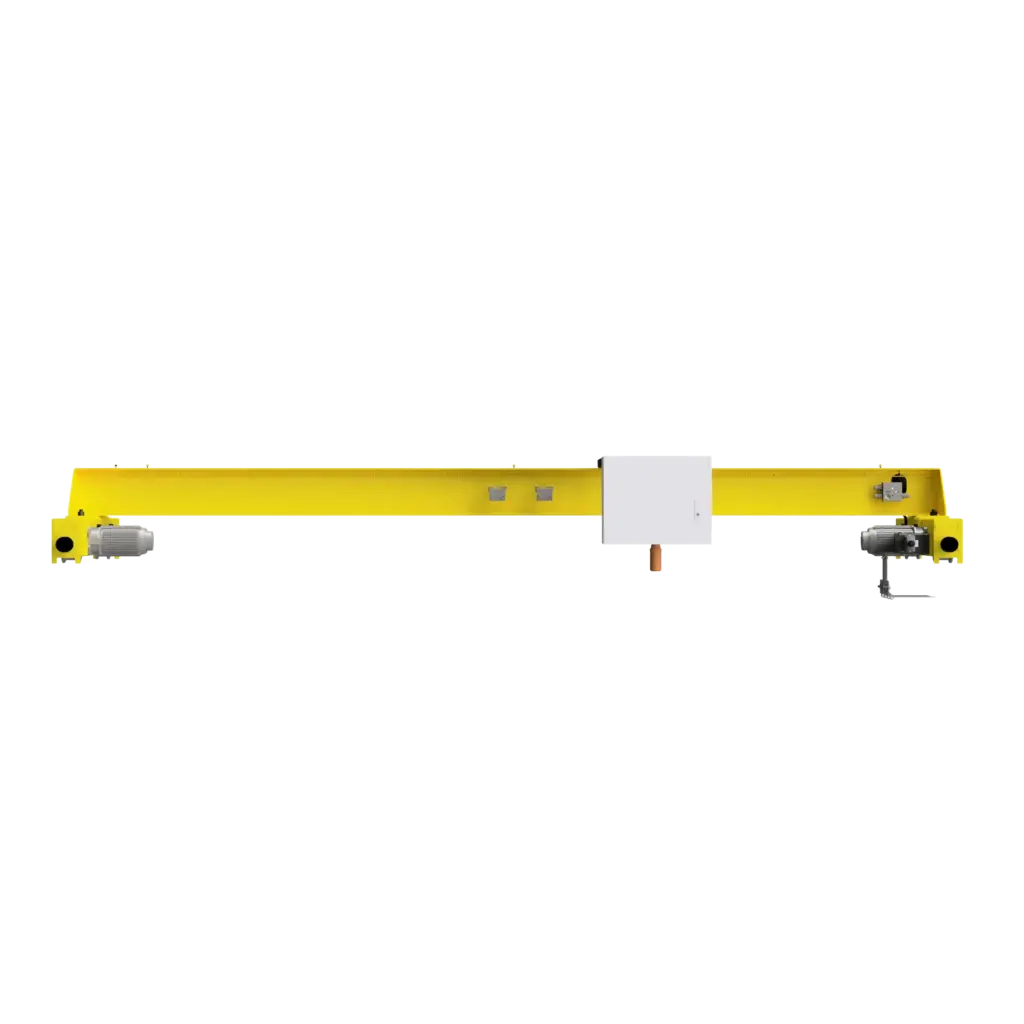

InCommand Top Running Bridge Cranes

Quality craftsmanship

Built with precision, InCommand bridge cranes reflect a high-quality fabrication process with meticulously clean component routing.

Specs

Capacity

1 - 50 Ton

Span

10' - 150'

Length

Unlimited

Height

Varies

Coverage Area

Square or rectangle

Options

Girder Configurations

Utilize a traditional single girder or increase your lift height with a double girder configuration.

End Truck Mounting

Select from traditional top mount, fully coped, and riser options.

Innovative product features

Festoonless wiring system

Our innovative festoonless wiring design significantly reduces the number of components that can fail. This streamlined approach not only enhances reliability but also minimizes maintenance, allowing you to focus on productivity without the worry of unexpected downtime.

Versatile mounting solutions

Whether you need to mount on an existing runway system, a new Pre-Engineered Metal Building (PEMB), or a freestanding runway system, PWI offers tailored options that perfectly suit your project’s application. Our innovative designs ensure seamless integration with your new or existing workspace.

Maximize lift height

Top running cranes are engineered to elevate your hoist as high as possible within your workspace, maximizing the lifting height of your crane.

Gallery

Real customers. Real results.

Custom Double Bridge Crane worked perfect for what we needed. Easy assembly, quality product, great price point, and prompt response when we had installation questions.

We ordered two 1 ton cranes with 30 foot and 20 foot spans. They came in early on their truck packaged perfectly. Everything we needed was in the package and it all went together perfect.

From the first day we met I was very impressed with the level of integrity and the service you offered. You answered questions quickly and followed through with changes we requested. I appreciated your patience in explaining the product and process.

FAQs

What is a bridge on a crane?

The term “bridge” is used to reference the part of the structure that travels along a fixed runway system. With a hoist mounted to the bridge, the operator gains 3 axes of travel.

What is the difference between top running and under running bridge crane?

Usually the building structure and workspace are the primary factors between choosing top running or under running (sometimes called under-hung) bridge crane. The difference is how the bridge beams attach to runway beams. Our team will work with you to design and build an overhead crane system that fits your workspace.

What is the difference between single girder and double girder?

Load capacity and span are the two primary factors considered when choosing between a single girder and double girder crane design. Our crane experts will walk you through the process of designing, building, and installing your overhead crane system that is perfect for your requirements and space.

Don’t confuse double girder for dual bridge (sometimes called two bridge) overhead cranes. A dual bridge has two independently controlled bridges that move up and down the runway beam.