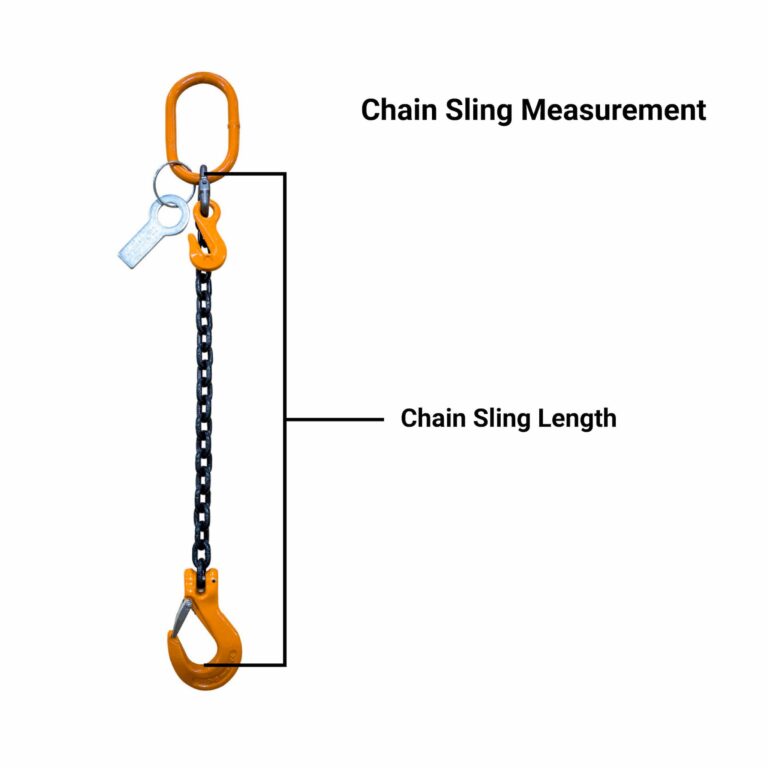

Starke Grade 80 Chain Sling

The Starke Grade 80 Chain Sling offers dependable strength and rugged performance for general-purpose lifting and rigging applications. Made from high-quality Grade 80 alloy steel, this chain sling is built to handle heavy loads while maintaining flexibility and resistance to demanding work conditions.

Ideal for construction, manufacturing, and material handling environments, the Starke Grade 80 Sling is available in a range of configurations to match your lift requirements.

Features

- Made from Grade 80 alloy steel for dependable performance

- Available in multiple leg configurations and lengths

- Fitted with high-quality hooks and components

Shannon Cox –

PWI provided me with the BEST customer service I have ever received! I purchased this item then when it shipped, I received an email and a phone call just to let me know it was on its way. Excellent quality in my product ordered as well.

Brad Dingman –

Excellent turnaround ordered on a Thursday received on a Monday. Excellent quality hoist chain. I plan on ordering two more.