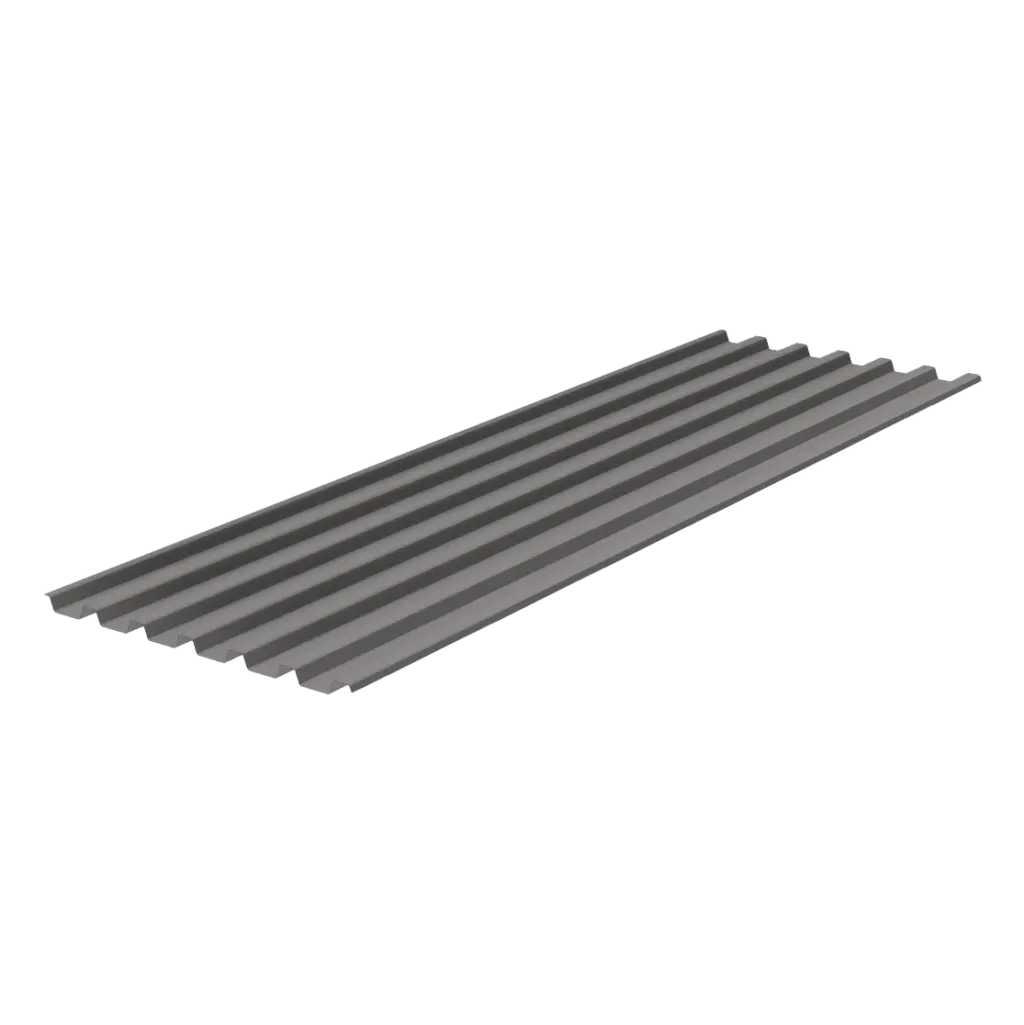

Form Deck

Support your next concrete pour

By creating a structurally sound base, our form decking optimizes the overall integrity of the flooring system, ensuring long-lasting performance and durability.

With its lightweight yet robust design, form decking simplifies the installation process while providing exceptional load-bearing capabilities. Ideal for commercial and industrial applications, our form decking allows for seamless integration with concrete pours, resulting in a flat, even surface that meets the highest standards of quality. Elevate your construction projects with form decking, the smart choice for reliable and efficient flooring solutions.

Specs

Steel Grade

A1011 CS Type B

Yield Strength

30 KSI

Sheet Length

40'

Width

36"

Height

1.5"

Innovative product features

Easy to Install

Get to pouring your next floor project efficiently with decking designed for quick lap installation.

Next Day Pickup

Deadlines matter. Get your project completed on time with our quick order processing.

Gallery

Real customers. Real results.

We needed a quick turnaround on B Decking for the canopy over the main entrance at Grand Design’s new Customer Support Center. PWI was able to deliver the material within 2 days of my order and kept our project on schedule.

The material arrived when they said it would and exactly as specified. I also enjoyed the simplicity of the website.

Great product, super fast service, highly recommended.

FAQs

What Are the Metal Deck Specs?

B Deck

- 1.5″ B Deck Resource Page

- Steel Grade: A1011 CS Type B

Form Deck

- Form Deck Resource Page

- Steel Grade: A1011 CS Type B

How do I order metal decking?

You can use our structural deck order form to place an order.

Will you provide equipment to help unload my structural deck order?

PWI does not provide any equipment to unload your order at your jobsite.

Do you offer returns for structural decking?

We do not accept returns due to all of the structural decking being cut to custom lengths.

Do you deliver metal decking?

Delivery charges are based on driving miles. This will be automatically calculated when ordering your metal decking.

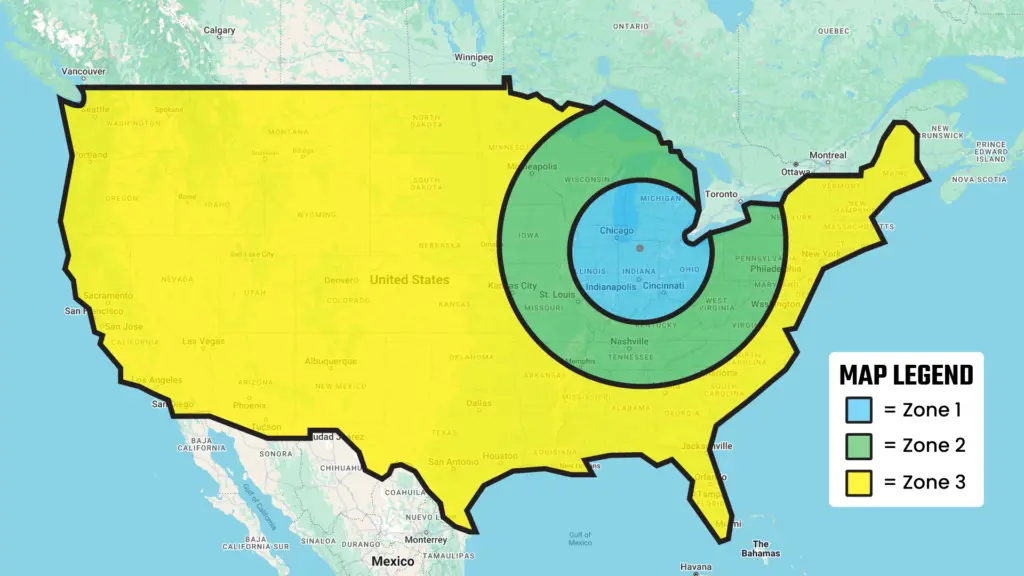

Customer Pickup in Nappanee: Free

Zone 1: 1-249 miles – $3.30/mile

Zone 2: 250-499 miles – $3.10/mile

Zone 3: 500+ miles – $2.90/mile

Can I Store My Metal Decking Outside?

It is recommended that all metal decking be shipped to the job site under a tarp and then stored out of the elements to avoid corrosion or surface rust.

This is especially important with White Bottom decking as surface rust from moisture shows up very quickly if left outside. We recommend that all decking be stored off the ground with one end elevated.

How Much Overlap Should I Allow When Ordering My Length?

A minimum of 2″ of overlap is required but we recommend 6″ of overlap.

What's the Galvanized Coating Thickness on the structural decking?

Our galvanized decking is G40 which has a designated coating of .40 oz/square foot.

How Do I Fasten the Decking to My Structure?

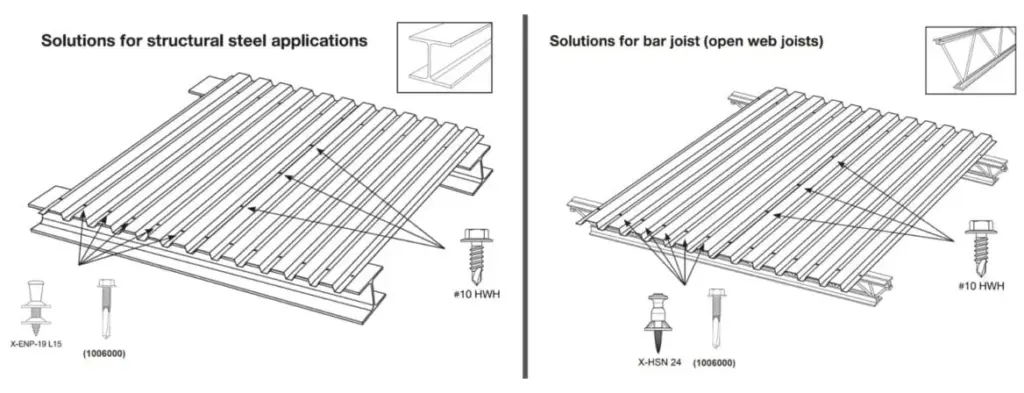

Attaching decking is a time-consuming process that requires a good level of accuracy. While some of our customers choose to attach decking using self-tapping screws, we highly recommend using the Hilti nailer method, particularly on larger projects.

The Hilti Stand-up Handle enables workers to efficiently and accurately attach sheets of decking from an ergonomic upright position as opposed to bent over and manually screwing.

Attaching B-deck and Form deck to either a structural steel beam or bar joist, we recommend using the Hilti DX-9 HSN and DX-9 ESP for each structural support respectively. Remember that you will need to use the appropriate fastener type in each application.

For attaching sheets of B-deck and FD (Form) deck with a Hilti Stand-up Handle, you must use the red strip Hilti #10 HWH screws to attach the sheets while standing on the upper decking panel. In the diagram, that means standing on the right side for B-deck and on the left for Form deck. Standing on the upper panel applies force to the overlap ensuring a clean connection.

To see authorized Hilti distributors and rental locations, visit Hilti’s website.

What Does a Square of Decking Mean?

A “square” of decking refers to 100 square ft of any type of decking.

What Gauges (Thickness) Are Available?

We have 20 and 22 gauge available for both B Deck and Form Deck. 20 gauge is .036″ and thicker than 22 gauge at .030″

Can I Choose a Custom Sheet Width?

B Deck and Form Deck don’t have custom width options available. It provides 36″ wide coverage which is standard in the industry. However, you can choose a custom length.

What Type of Roof Deck Do You Offer?

We offer 1-1/2″ B-Decking in either 20 or 22 gauge which is commonly used for commercial roofing applications spanning across purlins, joists, or other support members.

What is the Difference Between a Form Deck and a Composite Deck?

Composite Deck generally refers to a thin gauge, yet high yield strength decking that is designed to enhance the strength of the concrete being poured on top it.

Composite Deck has embossments in the metal designed to interlock and connect to the concrete as it is being poured which then adds to the strength of the floor structure as part of the design.

Here at StructuralDeck.com, we only offer Form Deck.

This deck simply has a standard smooth surface and is designed only to support the dead weight of the concrete while it is being poured, and then the concrete is self-supported.

Typically, a wire mesh product is used alongside Form Deck to reinforce the concrete to meet the engineered requirements.

We do not offer composite deck.

What is Form Deck?

Form Deck is a reliable and affordable way to form concrete for floors in new construction typically on top of a mezzanine platform or covered pit application.

How Do You Calculate Concrete for a Metal Form Deck?

That answer isn’t always the same. Check out our Form Deck Specs document for more details.

In What Applications Should I Choose White Bottom Over Galvanized?

Our White Bottom decking is painted with a brilliant reflective paint similar to the coating on a light fixture. This is recommended when you want the bottom or underside of your structure to have maximum brightness for a work space.

Galvanized decking is generally less cost per square foot but gives the same rated capacity. This can be used for general construction when the decking is covered by a ceiling or the end user is not concerned about brightness.

Galvanized is also recommended for form deck applications as the concrete being formed has moisture and wants to cause premature rust on the decking.

What Length Does Roof Deck Come In?

How long do you want it? You can choose a custom length between 2′-40′ with 1″ increments. We will roll form and cut it right to your specs.