Lever chain hoists can serve many purposes. From rigging operations to personal home projects or improving efficiency and safety in a production facility, you want to be confident in your purchase.

With so many lever chain hoists now on the market, we thought it best to provide some guidance on the most important features to look for and what we consider the top 5 lever chain hoists in 2023.

Our Favorite Lever Chain Hoists

As we see a trend of small unknown manufacturers producing hoists of un-verified quality, we need to set some important parameters to decide on the top five. They are:

- Reliability

- Features

- Price

Amongst the reputable manufacturers, we have found a solution that suits just about any application or budget. We’ll go into exactly what each of these features means later, but for now on to our list of the top five lever chain hoists available in 2023.

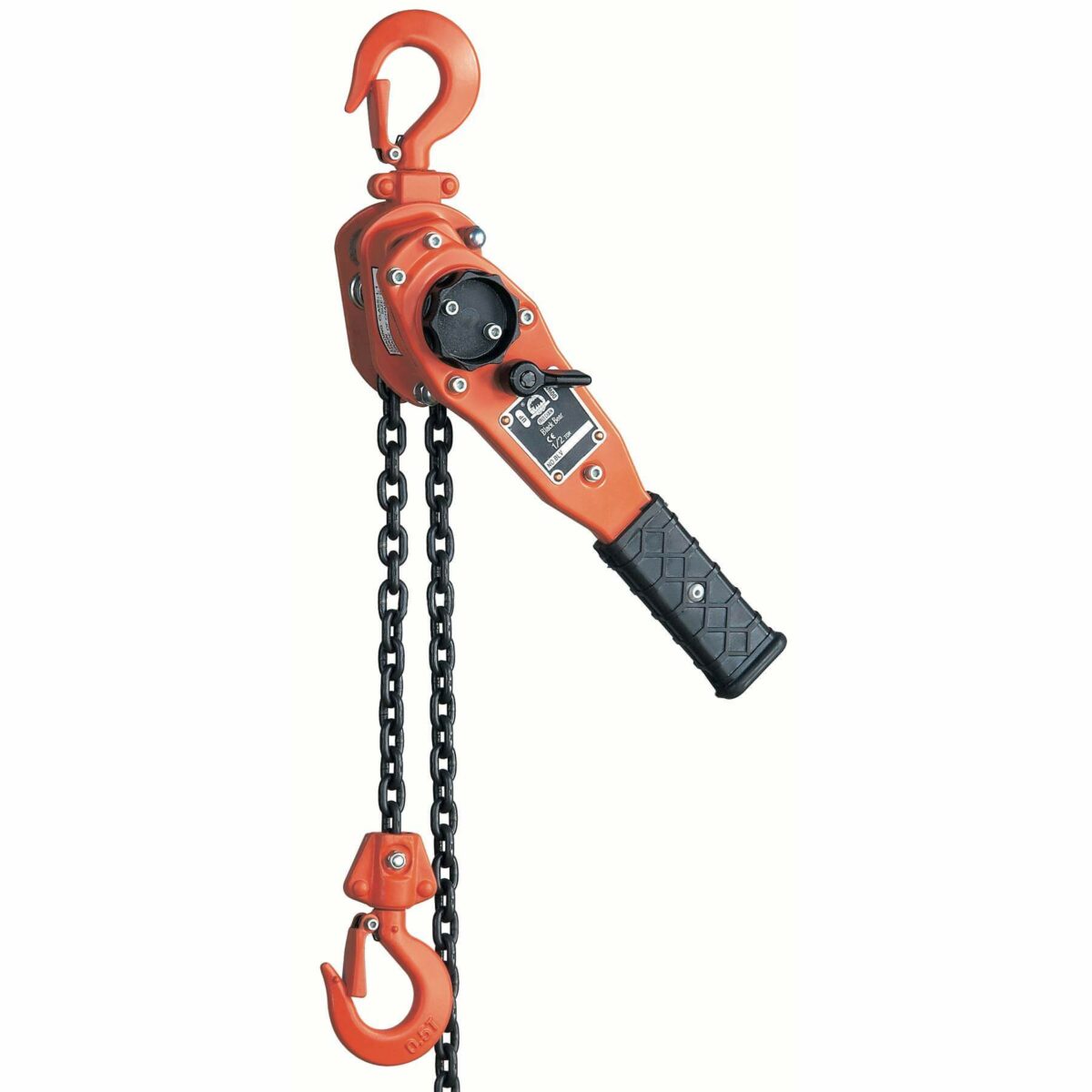

Black Bear YL Series Lever Chain Hoist

The Black Bear YL Series Lever Chain Hoist is more of a heavy-duty lever chain hoist featuring 360-degree rotating upper and lower hooks fitted with safety latches. The YL Series lever chain hoist is available in a wide variety of weight (¼ to 9 ton) and chain length (5’ to 20’) options.

The hoist covers use pre-formed steel for enhanced protection against bumps and shocks. It features a hand wheel that allows adjustment for very light loads and allows you to slacken the chain before attaching the hook to a load. A load chain guide helps to keep the chain aligned to prevent lateral movement of the load and increase reliability and longevity. It also includes a load brake and dual ratchet pawl system for improved safety.

An overload device can be retrofitted to the hoist at any time for models up to 9 tons. This will prevent the operator from accidentally overloading the hoist reducing the risk of injury and costly damages.

CM Series 653

The CM Series 653 range of lever chain hoists have a ¾ to 6-ton capacity with chains of 5, 10, 15, and 20 feet in length. It has a durable but lightweight impact-resistant steel body and plated surfaces for easier maintenance. It features a 360-degree rotating steel hook with safety latches for rigging and load attachment.

The lower-capacity ¾ and 1½-ton models are now available with a shorter lever making the operation easier and more suitable for tighter work environments. Every model uses an ergonomic rubber lever grip to prevent slippage and aid operator comfort. An enclosed Weston type braking system ensures the brake system stays dry and free of dust for positive load positioning and roller chain guides help minimize any risk of jamming. It also meets ANSI B30.16 standards.

CM Series 602 and 603 Mini Lever Hoists

If you are looking for a highly portable and inexpensive option, the CM Series 602 & 603 Mini Lever Hoist offer the same quality and feel as a much larger lever hoist. Available in ½ and ¼ ton options with a 5’ or 10’ chain, they are ideal for portable use and are small enough to fit in a toolbox or the optional carry bag with a shoulder strap.

It uses a fixed-position forged steel hook with safety latches and the compact design makes it easy to rig in confined spaces. A durable rubber grip helps prevent slippage and single-hand use for load adjustment and freewheeling for attaching a load.

The 602 and 603 models differ in chain treatment. The 602 uses a zinc-plated chain and the 603 a gold chromate chain for enhanced corrosion protection. Both hoists are metric-rated and feature a lifetime warranty.

CM Tornado 360° Lever Hoist

The CM Tornado 360° Lever Hoist stands apart from all other lever hoists on the market with its 360-degree Sidewinder™ lever. Designed for improved ergonomics and efficiency, the lever can be rotated a full 360 degrees in a cranking motion to significantly reduce the time it takes to hoist a load. It can also be used in the more conventional back-and-forth motion across a wider range to reduce the risk of wrist problems or injury that can occur from repeated long-term use.

The lever has a kinked design to allow the operator to stand in line with the load chain for better ergonomics. The handle also folds out in both directions meaning that any operator can use the lever safely regardless of their dominant side. A thumb-operated lever allows you to easily switch between positive, negative, and neutral drive positions with a lockout between each mode for added safety.

The CM Tornado 360° lever hoist uses a lead-tested zinc-plated chain for corrosion protection and comes with a lifetime warranty. It also meets ASME B30.21 regulations.

Vestil PLH Lever Hoist

The Vestil PLH Lever Hoist is a very high-quality and rugged hoist that can be operated from any angle with 360-degree swivel snap hooks. It uses an alloy steel chain grade 100 to provide high strength with less weight and rust resistance. The reduced overall weight makes it practical for transport and it includes a carry bag.

The disc brake-style braking system is claimed to provide four times the rated capacity in braking load and each unit is tested to 150% of capacity for certification.

It is a relatively inexpensive lever hoist but among the best on Amazon and suitable for personal use. Another plus is that while it is made in China, Vestil has an office in the U.S.

Qualifications for Making This List

Each of these chain lever hoists has impressed us with its features and the models we have included in the list are designed to apply to the widest range of uses and budgets possible.

But what do each of these features mean for real-world performance and value for money?

Reliability

As with any hoist, reliability is paramount. A hoist failure can result in a halt to production, downtime, and business losses. But reliability is a difficult metric to measure, so instead we look to features that combine to create the most reliable hoists.

For a lever chain hoist, the design, construction, warranty, manufacturer reputation, and braking system all play a part in determining the best products to invest in.

Features

A lever chain hoist may appear relatively simple, but there are several features to consider that will influence application suitability and reliability.

Construction and Materials

Lever chain hoists can suit a wide range of different lifting applications. Depending on the duty cycle, weight capacity, length, and location, you need to look for specific characteristics.

If portability is a primary concern, you need to look for a lighter-weight hoist body or chain to reduce overall weight. You would ideally have a smaller body to make it more practical for transportation as well.

If durability is a primary concern, you would want nothing less than cold-forged steel for the hoist body because it will provide sufficient impact and shock resistance.

Steel hook

Rigging a lever chain hoist is an important consideration. Depending on where it is done, access to the rigging point can be an issue. For this reason, it is advised to choose a hoist that has a 360-degree rotating steel hook with a safety snap closure.

Chain length

The chain length will vary depending on the rigging point of the hoist and the size of the load. Chain lengths normally vary between 5 and 20 feet and are available in 5-foot intervals.

Lever Ergonomics

Considering a lever chain hoist is operated by a lever, its ergonomics are hugely important in improving efficiency and reducing the risk of injury for the operator. A non-slip handle also helps increase safety by reducing the chances of slipping.

Braking System

Every lever chain hoist needs to incorporate a load brake system. This means that the operator can stop the hoisting at any time without the risk of the load being dropped. This reduces the risk of unnecessary damage to the load and injury to the operator.

Ease of Use

The length of the lever will have an impact on how much force is required to lift the load, but so can a planetary gear system. This works by gearing down the input to produce a very small amount of lift. In other words, a low-force input will produce a high-force output. It means that the operator does not need to exert much force to reduce the risk of injury.

Manufacturer’s Warranty

While it may not be necessary, it is always a good indicator of manufacturing quality when a warranty is included.

Accreditation

When choosing a lever chain hoist for use in a production or manufacturing facility, you must check that it complies with OSHA standards for manually lever-operated hoists and ANSI/ASME B30.21C.

Price

The question of price is case-specific. Depending on the lifting requirements and duty cycle, a hoist is going to vary in how much return it provides a production or manufacturing floor.

As a rule of thumb, higher load requirements and longer chains will inevitably lead to a more expensive hoist due to the materials used. Hoists that are more innovative in their features will also tend to be more expensive because of specialized manufacturing processes.

So, it is fair to say that a more expensive hoist will be a better one, but whether it suits your requirements is another question.

Where to Get the Best Value on Lever Chain Hoists

If you’re looking for the best deals on lever chain hoists, you will likely find them at Hoist Zone which stocks four of the five best lever chain hoists we have listed in this article. For a single hoist purchase, there is no better place.

But if you are an industry professional looking for a bulk purchase and want the best deal possible, contact PWI for a free quote. We will help save your business money and get you the highest quality products available, fast.

![New Construction vs Mezzanine [PDF]](https://feqfc6pbctcc-u6419.pressidiumcdn.com/wp-content/uploads/new-construction-vs-mezzanine-pdf-464x600.jpg)