A below-the-hook lifting device is designed to handle a variety of loads with challenging characteristics like an awkward center of gravity or handling products that are more fragile than others. They can also be used to join two or more overhead cranes together to increase the overall lift capacity that the operator may have available to them.

Essentially, they provide a solution to lifting just about anything!

What is a below-the-hook device?

A below-the-hook device is a custom lifting fixture designed to lift a specific item repetitively with increased efficiency and safety. There are various types of below-the-hook devices that can be categorized in three ways:

- Sling

- Spreader beams

- Custom lifters

Each of these categories serve a different type of load.

Examples of Below-the-Hook Devices

There is a huge range of BTH devices available as stock and customizable stock products as well as fully bespoke solutions for extremely specific situations. Let’s take a look at the more commonly found below-the-hook devices available, their uses, and how they can be customized:

Slings

Sings are a more universal type of lifting device that can be used in different configurations to spread the picking points across an object and increase its lifting capacity.

Chain Slings

Designed for generic use, chain slings are wrapped around the object. They are customizable and flexible making them suitable for any shape an object. The chain is available in different grades and thicknesses that will influence specific load capacity. Depending on the configuration in angle and the number of chain legs, the capacity can reach up to 22,900 lbs.

Customizable options for chain slings include:

- Chain grade

- Chain thickness

- Chain length

- The number of legs

- Hook adjusters

- Hook style

Nylon Sling

Also designed for generic use, a nylon sling is wrapped around the object and looped onto the hoist hook either by eyelets or around the continuous loop of the sling. The weight capacity of a nylon sling is determined by different characteristics and configurations:

- Number of plies – one or two

- Sling width – one, two, or three inches

- Attachment – continuous loop or eyelets

- Grab method – vertical, choker, vertical basket

Spreader Beams

A spreader beam extends the picking points and picking load across an object to avoid potential damage caused by an increase in force. They are used to balance uneven and delicate loads, especially when headroom is limited. Spreader beams can be used on both forklifts and hoists.

Adjustable spreader beam

By using two lifting points instead of a single one, an adjustable spreader beam distributes the weight of a load evenly. This helps to balance loads that can otherwise be awkward to lift. The spreader beam can be adjusted in width to lift small and large objects up to four tons in weight.

Economy Spreader Beam

An economy spreader beam takes all of the efficient characteristics for balancing a load but with a fixed length. The advantage of its simple design means fewer things to go wrong and lower cost.

Lifters

Custom below-the-hook lifters are used for loads that are awkward to handle and require a specific type of picking method. They are preferable over a sling mainly due to their increased efficiency for repeated use with the same objects.

Anver Vacuum Lifter

An Anver vacuum lifter is an efficient and completely custom industrial lifter that is made to order. The four key components—a vacuum generator, beam, crossarms, and vacuum cups—can be configured to suit a specific load. The vacuum cups can be used to help to spread the load across multiple picking points without damaging the object and to pick up multiple objects at the same time. Lifting applications include:

- Food industry

- Metal sheeting

- Vinyl or plastic sheeting

- Countertops (dependent on capacity)

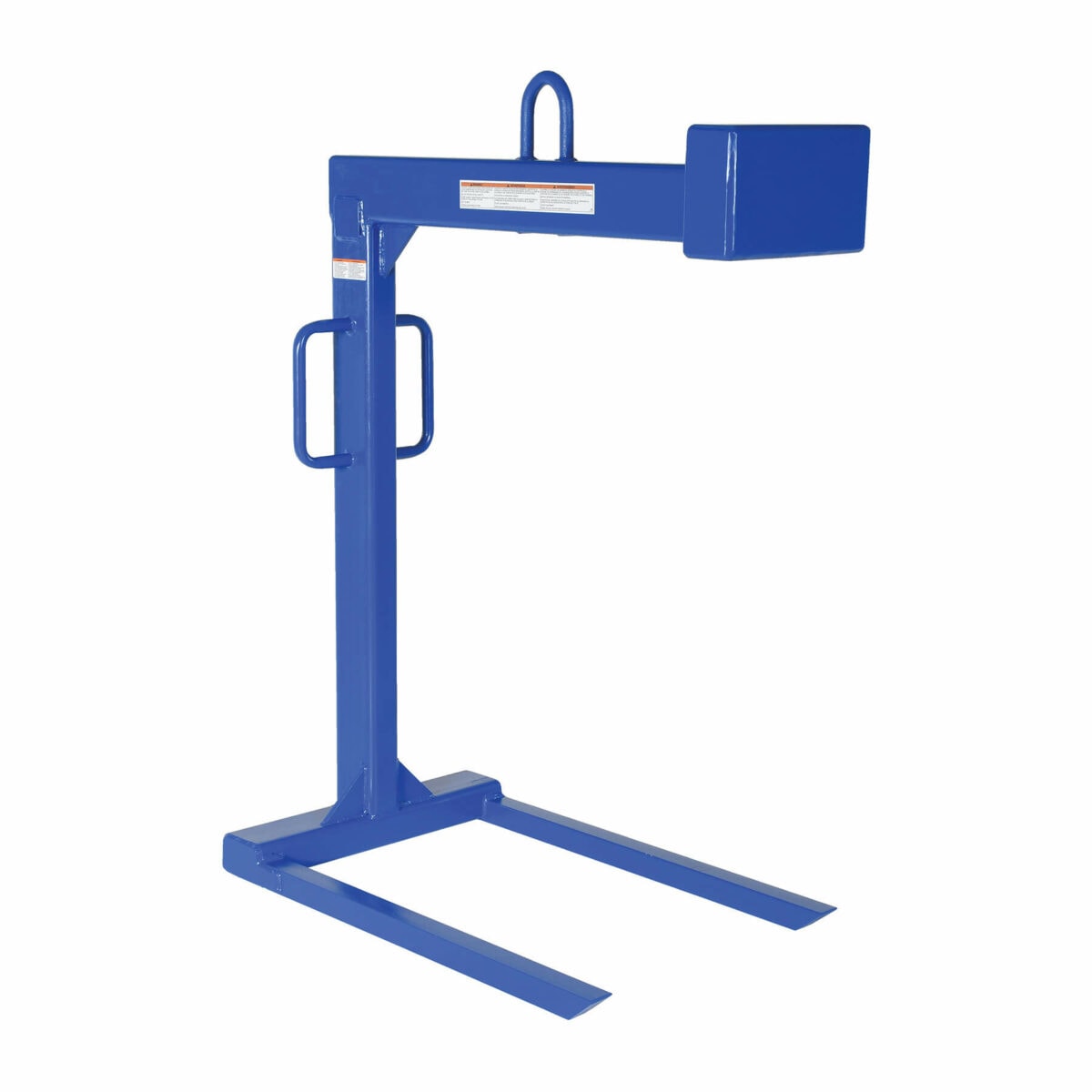

Vestil Pallet Lifters

A pallet lifter allows users to efficiently move materials loaded on a pallet or stacks of pallets at the same time. A pallet lifter is only hooked from one side of the pallet so there is a risk of swaying. For this reason, they are often equipped with additional handles for personnel to aid the maneuvering of the load.

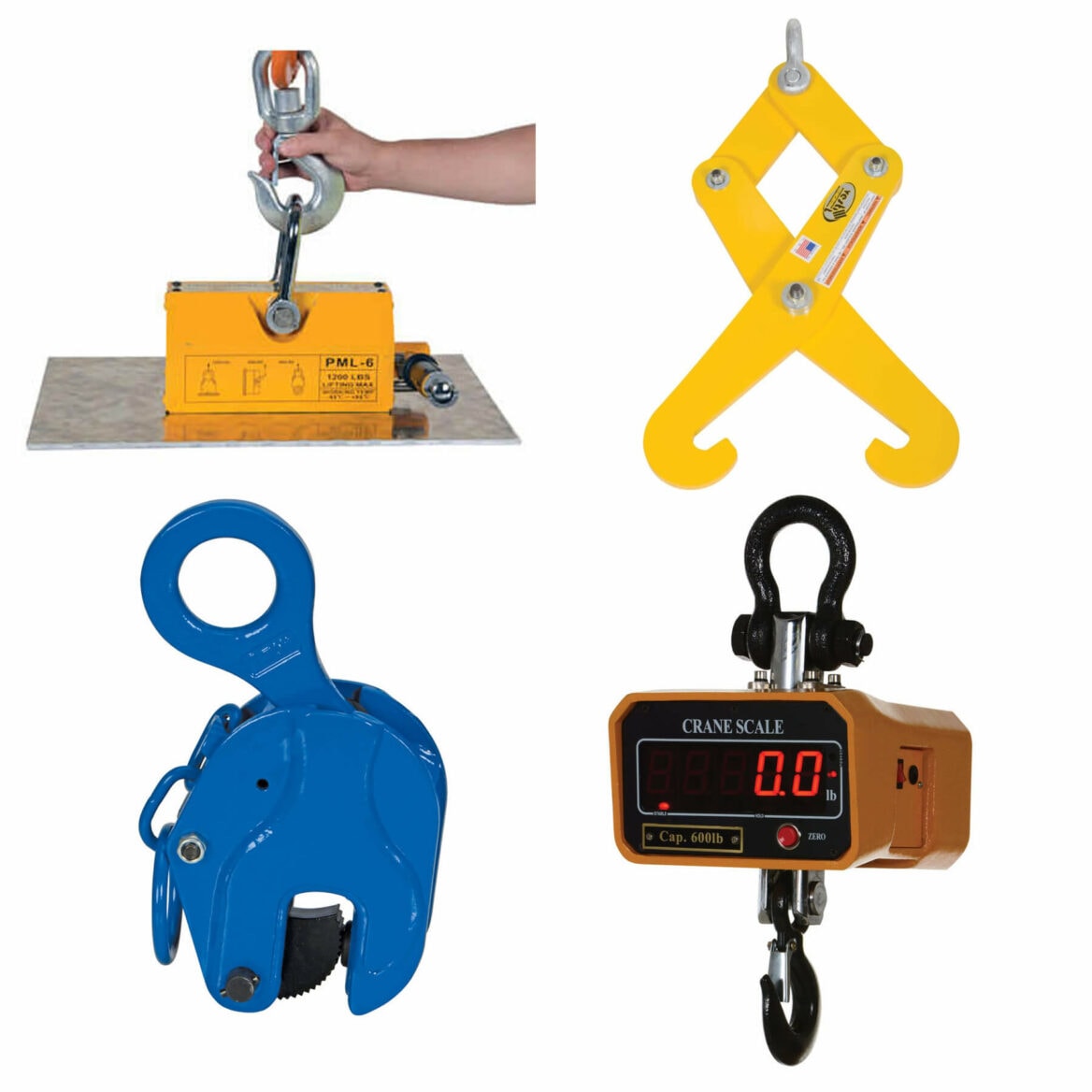

Plate Clamps

These types of lifters are designed specifically for lifting plate materials such as countertops, sheeting, wood, etc. They are available in different versions to lift plate material in a vertical or horizontal orientation. Often referred to as “friction gripping lifters” this lifter can also incorporate a positive locking mechanism to ensure safer material handling.

Beam Tongs

I-beams are notoriously awkward to lift because of their shape and length. Using a beam tong, an I-beam can be easily and safely lifted. The heavy-duty tong creates a clamp on the upper flat face of an I-beam. It is important to find the center of the beam before lifting to avoid excessive lean.

Crane Scale

It is often difficult to weigh heavy-duty equipment, especially when an industrial floor scale is not accessible or there is insufficient space for one. A crane scale allows for objects to be safely and accurately weighed regardless of their size. It can also allow you to accurately weigh objects before loading them into a semi to avoid exceeding weight restrictions. They are also commonly used in the food industry and for hunting.

Abaco Little Giant lifter

The Abaco Little Giant Lifter is designed for lifting slab and plate material with the additional security of a locking latch mechanism. They are similar in function to a plate clamp but are a more secure option with an automatic pneumatic operation that opens and closes the mechanism as the object is lifted up and down.

Are below-the-hook devices necessary to use with my hoist and crane system?

Yes, in almost every instance you will require some sort of below-the-hook device for a specific application. This is simply because you cannot use a hoist without some sort of BTH device, such as a nylon sling.

Below-the-hook devices need to be rated and inspected separately to the lifting device (crane or forklift).

As with anything to do with lifting, you need to be wary of regulatory compliance. While OSHA does not have any specific regulations, they do recognize standards set by ASME (The American Society of Mechanical Engineers), particularly standard B30. You can check the specifics of the regulation via this OSHA BTH resource page.

Where can I buy a below-the-hook device?

Our friends at Hoist Zone have a large selection of slings, spreader beams, and custom lifters to suit absolutely any application which you can purchase directly from their site. If you aren’t exactly sure what below-the-hook device is best for your needs or just have some questions, contact PWI today and our expert team will be happy to help.

![New Construction vs Mezzanine [PDF]](https://pwiworks.com/wp-content/uploads/new-construction-vs-mezzanine-pdf-464x600.jpg)