Is your business running efficiently?

If you aren’t using Variable Frequency Drives (VFDs) in your business and you do any kind of manufacturing, the answer is probably “no”.

VFDs have been a game changing device for many industries and devices — from HVAC systems to crane hoists.

Here we’ll focus on the latter and how VFDs affect overhead crane systems.

What is a VFD?

VFD stands for Variable Frequency Drive.

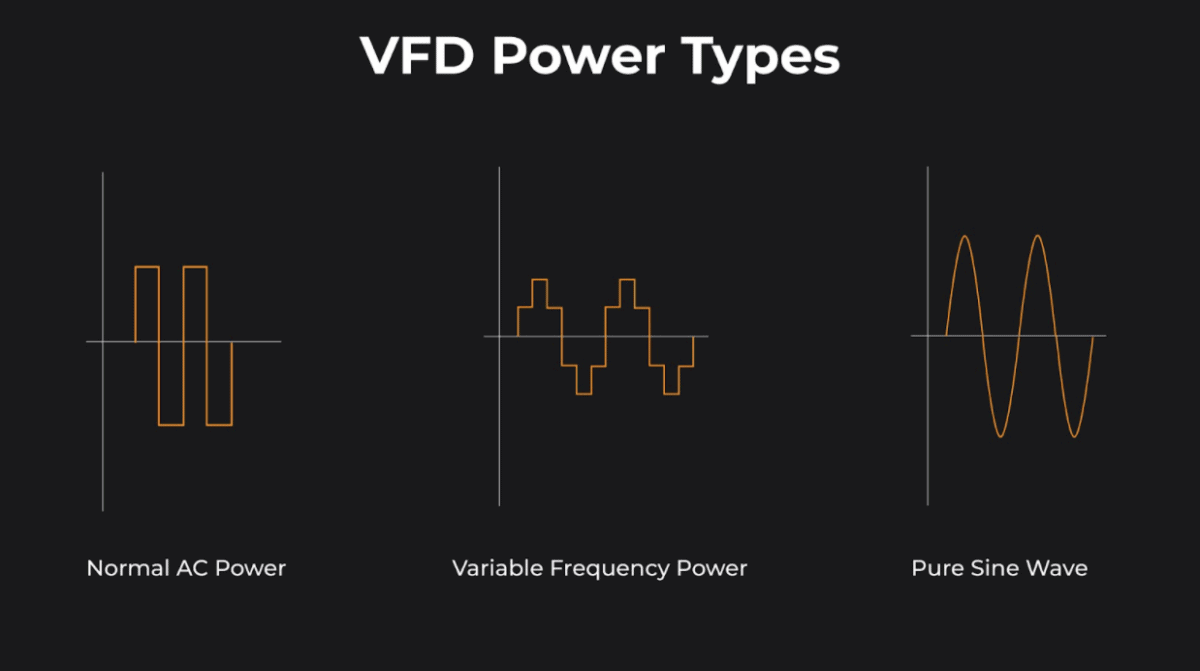

What they do is vary the frequency of an AC motor by creating a sine wave pattern in the electric signal.

So instead of being “on” or “off”, the VFDs can allow motors to operate at levels in between.

This allows for better motor control, adjustable speed control, and acceleration and deceleration ramps.

We can understand this better with an example.

Let’s say we have a crane that does not have a VFD.

When we raise or lower the load, the motor will be operating at full power.

If we want to lower the load from 20ft to 10ft, we’d do it by lowering the load at full speed using the motor and then stop it via the brakes on the crane.

Now if we had a crane that had a VFD, we could control the deceleration as we lower the load.

So when we put the breaks on, the speed could be much slower and not put as much stress on the brakes.

That example would be comparing something like a single speed motor to a motor with VFD.

But there are other kinds of motors other than single speed.

Single speed motors were pretty common before VFDs came to cranes, but another popular kind of motor was the 2-speed motor.

A 2-speed motor, as the name implies, operates only at two speeds.

So it’s easier on the brakes than the single speed motor, but cannot achieve the same range of speed control as a crane equipped with a VFD.

Pros

Let’s look at some of the benefits of VFDs for crane systems.

Less Wear on Components

One of the most obvious benefits of VFDs on cranes is the reduced wear on the crane’s brakes.

In cranes that operate without VFDs, brakes could need replacing every few months due to the mechanical wear.

VFDs eliminate a lot of this wear by slowing down the crane so the load can stop in a more controlled manner.

Brakes aren’t the only thing that benefit from adjustable acceleration and deceleration.

Many components on a crane are more prone to wear from the sudden stops that occur without a VFD.

The drive train, end trucks, and trolley are all components that experience less impact when a VFD can slow the deceleration and acceleration.

Adaptability

Unlike single speed and 2-speed motors, cranes with VFDs are programmable.

So instead of having two speeds to choose from, you could have 30-40 or even more.

Some of the higher end VFD systems can have hundreds of control parameters programmed to them.

VFDs also don’t suffer from some of the overheating problems that soft start devices can have.

This capability makes cranes with VFDs super adaptable and useful in a wide range of different applications.

Increased Safety and Maintenance

VFDs send and receive a lot of information to and from the motor.

Using that information the system can determine if the hoist is overloaded.

If the system does determine that the motor is overloaded the lifting is stopped.

This feature can help prevent mechanical fatigue.

The software in VFDs can also allow for operators, maintenance personnel, and remote third-parties to program, monitor, and troubleshoot the VFDs drive systems.

So you can receive fault codes and other diagnostics with a crane system using VFDs.

This is a great benefit as it gives you more information if your crane motor needs maintenance.

Cons

Installation

A poorly installed VFD can cut into the benefits.

If you’re upgrading your crane systems to a VFD system, it’s important to make sure the electricians who work on it have proper training and experience installing VFDs.

Or if you are thinking about adding a crane system to your building and want it to come with a VFD, make sure you get it from a reputable dealer.

PWI has had many years of experience with VFDs and many of our customers love the benefits that they provide, but we’ve had lots of experience with crane systems.

Not every crane company is as concerned about their quality and customer satisfaction as PWI is, so doing research on who you hire is crucial to avoiding the cons of VFDs.

How to Get the Most Out of a VFD

Get Professional Installation

A little more time spent getting a proper installation will save your business from the problems associated with an improperly installed VFD.

Also knowing how to make the most out of the VFD’s programmability is another important way to get the most out of your VFD system.

Know Your Needs

Knowing what your needs are will also help you choose the right VFD system.

The lower end systems can have 30-40 different speeds programmed to them.

If that is within your specific needs then you may be able to go with a more affordable system.

If you need more than 40 different speeds, going with a higher end system is probably your best bet.

Conclusion

VFDs have been around for a while but not every company who uses cranes knows about the amazing benefits that come with these systems.

VFDs can save you a lot of money over the life of your crane, in reduced maintenance and increased efficiency.

Here at PWI, most of our cranes use VFDs because of their efficiency and improved performance over other crane motor systems.

If you want to learn more about cranes that use VFDs and how they might benefit your business, call PWI and we will help you find exactly what your business needs.

![New Construction vs Mezzanine [PDF]](https://pwiworks.com/wp-content/uploads/new-construction-vs-mezzanine-pdf-464x600.jpg)