Is a gantry crane the best solution for your work area? We take a look at all of the different options available including portable gantry cranes, full gantry crane systems, and how they compare with bridge cranes.

Gantry crane systems come in a very large variety of options and can be used in an equally large range of applications. Everything from hoisting car engines to loading storage containers in cargo shipyards, there is a gantry crane perfectly suited to the job.

This article is going to take a deep dive into all of the applications of a gantry crane and help you make the best purchase decision for your plant or workspace.

What’s the Difference Between a Bridge Crane and a Gantry Crane?

A bridge crane system—otherwise known as an overhead crane or overhead bridge crane—is typically mounted inside of the building in which it operates. The frame is fixed to the building structure using beams and a moving bridge spans them. In cases where the building cannot support the crane, a standalone structure is built to support it. This is called a “freestanding” overhead crane because it doesn’t rely on support from the building and can be placed anywhere, including outside. Whether freestanding or supported by the building structure, a bridge crane system is fixed in place where it is installed.

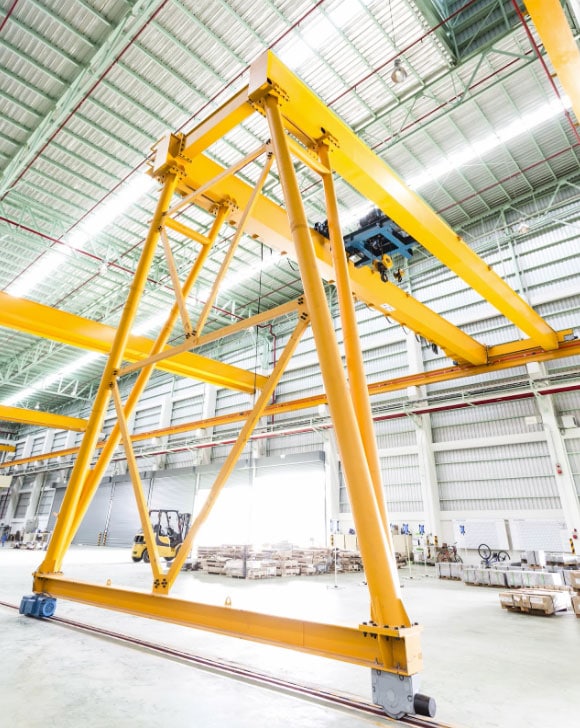

In comparison, a gantry crane is typically not mounted to the building structure. Instead of being fixed in place, it sits on caster wheels or a floor track which give it flexibility to be used across multiple applications in a production space. A typical A-frame construction supports the overhead beam.

These two crane types vary in their lifting capacity mainly due to their construction. As you might expect, with the bridge crane system being fixed in place, it has a generally higher lifting limit (up to 100 tons). Gantry cranes are not as capable, but typically lift loads of up to 15 tons.

That’s not to say a gantry crane cannot be designed and built that lifts much more!

Another big difference is that a gantry crane doesn’t have a runway because it rolls on wheels or a track. This keeps the overhead area clear of a runway and eliminates supporting columns which depending on the application may be an important factor to consider.

They also differ in their purpose. Gantry cranes are generally used to service a small or specific area and function. Bridge cranes can be used to serve a large area where multiple processes are being performed, like an assembly line.

Different Types of Gantry Cranes

Possibly the best thing about gantry cranes is that they span a huge range of uses. From the very small portable cranes to huge full gantry crane systems used in shipbuilding, here is a breakdown of the specific types of gantry cranes and why they are especially well suited to their purpose.

Portable Gantry Crane System

A portable gantry crane is considerably smaller and lighter-duty than the previous two gantry systems. It has no fixed location and runs on casters or rubber wheels allowing it to be easily moved around any facility to hoist and support various materials and load types. The portability makes this gantry system highly effective at being available when needed but hidden when not to save space and improve floor space flexibility.

Adjustable (Telescoping) Gantry Crane System

An adjustable gantry crane is designed to have variable dimensions to suit different working environments. This includes adjustable placement along the I beam (the span of the gantry), adjustable height, and adjustable base width. The system has the added benefit of being far more maneuverable around the work area.

Full Gantry Crane System

Arguably the most popular configuration of a gantry crane is a full gantry crane system. This is composed of two supporting legs—one at each side—which move along two rails on the floor, normally in a straight line. The floor rails are embedded in the top surface of the floor to create a flush surface that allows motorized equipment such as forklifts, carts, and trucks to roll over it without disturbance.

Semi-Gantry Crane System

While a gantry crane does not need to be connected to a building, it can be. A semi-gantry crane system can be designed in such a way that one leg rides on wheels or rails, and the other side uses a runway system connected to the columns of a building. This can be internal or external depending on the requirements. The main benefit of a system like this is that it saves considerable floor (work) space and, unlike a bridge crane, it does not require two runways.

Other Types of Gantry Crane Systems

Because gantry cranes are used for such a huge variety of applications and their load capacity can range from one to 22,000 tons (yes, you read that correctly), there are many different versions of the four primary classifications of gantry crane. These include:

- Single girder gantry crane

- Double girder (semi) gantry crane

- Truss gantry crane

- Box gantry crane

- L-shaped gantry crane

- U-shaped gantry crane

- Workstation (caster-mounted) gantry crane

Are All Gantry Cranes Portable?

No, not all gantry cranes are portable. While all gantry cranes will be able to move, high-capacity gantry cranes can only move across a path designated either by rails alone, a combination of rails and wheels or as a semi system with a wall-mounted I beam.

What Industries Use Gantry?

Thanks to the huge variety in gantry crane design allowing for varying sizes and lifting capacity, pretty much any industry can use some form of gantry crane.

While there are many applications where a gantry crane can be used almost interchangeably with an overhead or bridge crane, there are a few specific instances where a gantry crane is far superior.

They are most commonly used in manufacturing facilities, shipyards, scrap yards, railyards, steel mills, and special construction sites. However, smaller telescopic gantry cranes can be commonly found in body shops, and wood/metalworking shops to aid in hoisting and supporting heavy and awkward loads.

The daily operations of an engine repair shop in particular benefit hugely from the flexible size and portability of an adjustable gantry crane. It can easily span the width of a vehicle and it provides a true vertical lift for the engine.

An engine repair shop is usually a space in constant flux where vehicles and parts are moved between locations, plus the size of vehicles can vary a lot. An adjustable gantry crane is a preferred solution here because of its adaptability in size and ease of positioning. It’s also small enough to not get in the way of the mechanic. When combined with a chain hoist, the mechanic can precisely lift or lower the engine for maintenance, removal, and installation.

Looking at the other end of the scale, gantry cranes are crucial to shipbuilding. Wide-spanning gantry cranes in particular are used to move heavy tools and parts around inside of the hull.

The use of a gantry crane specifically over an overhead crane is due to shipyards being huge spaces that benefit by not having support columns in the way. A gantry crane is self-supporting and the use of rails at ground level enables the free movement of vehicles and people maximizing the use of space –something especially important when working on this scale.

Is a Gantry Crane Right for Me?

There are a few factors that will determine whether a gantry crane is the best solution for you.

The start-up cost is an inevitable factor in making your decision. While a gantry crane can easily cost a very large sum of money, the entry point is far lower than most crane systems. For around $5,000, you can purchase a gantry crane capable of lifting 1-2 tons. For many plants, it would be sufficient. For heavier weight requirements, a portable gantry crane capable of lifting up to 5 tons will cost you around $10,000.

Another detail in the cost of a crane will not just be the installation, but how the installation will disturb plant operations. If the operations need to be paused to allow for installation, or if the installation needs to take place outside of regular hours or over public holidays, there will be an additional cost incurred.

Portable gantry cranes are extremely easy to install by the end-user because they do not require any structural modifications to your plant or workspace.

Another important consideration is how you will be using the crane. Will you use it constantly throughout the day? Are there multiple areas where you could use an overhead crane? A portable gantry crane can be moved to different production areas when it’s needed.

Will you need to use a crane constantly throughout the day? Are there multiple areas where you require hoisting and maneuvering? How is your work space distributed? Do you have sufficient floor space for a portable gantry crane? A portable gantry crane can be easily moved to different production areas when it is needed, and stored when it is not required.

Still Have Questions?

Getting the most out of your workspace is important. It doesn’t matter if you have multiple plants or a small workshop in your garage.

We are committed to helping American businesses maximize production. Call our main office at (574) 646-2015 to talk to an overhead crane expert or get a free quote today.

![New Construction vs Mezzanine [PDF]](https://pwiworks.com/wp-content/uploads/new-construction-vs-mezzanine-pdf-464x600.jpg)